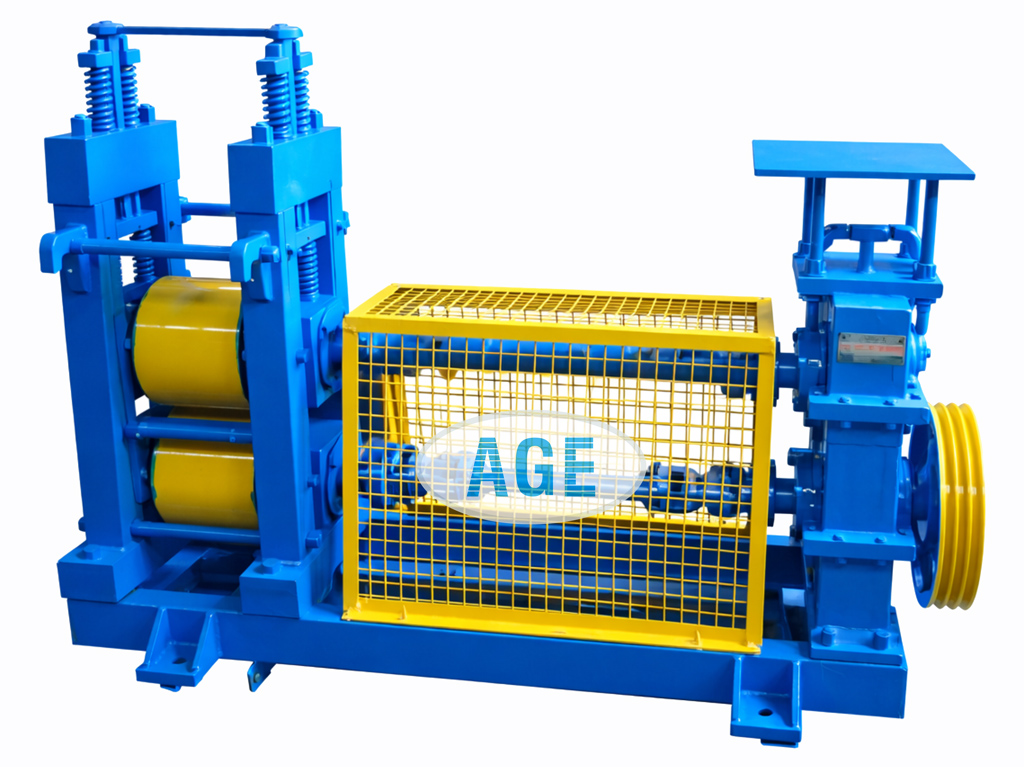

Pinch Rolls and Tail Breakers for Rolling Mills

Top Manufacturer & Exporter of Pinch Rolls and Tail Breakers for Rolling Mills in India

A.G. Engineers is a leading manufacturer and exporter of premium-quality Pinch Roll/Tail Breaker systems used in modern steel rolling mills. Built using advanced manufacturing technology and high-grade raw materials, our pinch roll/tail breaker units are engineered for precision control, heavy-duty performance and long service life. Designed specifically for TMT bar mills, structural mills and hot strip rolling lines, our systems support seamless material flow and enhance process automation.

We offer Cantilever-type and Pneumatically operated Pinch Roll/Tail Breaker assemblies up to 550 MM Center Roll Spacing (CRS), engineered to withstand harsh mill conditions and high-speed operations. These units are fully customizable and comply with both Indian and international quality standards, making us a trusted partner for steel producers and OEMs.

- Cantilever & Pneumatic Design: Top roll is pneumatically lifted or lowered; bottom roll is height-adjustable via screw-down for pass-line alignment.

- Precision Bar Control: Helps grip and guide bars post-finishing stand, crop shear, or cobble shear with minimal deviation.

- Integrated with PLC & HMD: Receives signal from Hot Metal Detector (HMD) through PLC for precise actuation and braking.

- DC Motor Drive: Driven by high-torque DC motors through a gear system and Cardan shafts for uninterrupted rotation.

- Selector Switch Mechanism: Tail Breaker includes a selector switch that directs the bar into one of two twin channels post-braking.

- Heavy-Duty Steel Construction: Fabricated housing with wear-resistant liners and anti-friction bearings for maximum operational life.

- Leak-Proof Design with Forced Lubrication: Oil-tight steel housing designed to connect with external pressurized lubrication systems for bearings and gears.

Material : M.S. Prime Plate, Graded Cast Iron

Base : Mild Steel Prime Plate Fabricated

Size : 205 mm to 360 mm (as per the requirement of the mill)

Chocks : Steel Chocks fitted in Pinch Roll for Spherical Roller Bearing

Bearing : Imported Spherical Roller Bearing

Shaft : Cardon Shaft

Gear Box : Includes Forged Steel Single Helical Gears with all accessories

Barrel Length : As Suitable to the Pinch Roll.

Our Pinch Roll and Tail Breaker systems are integral to:

- TMT Bar Rolling Lines – controlling bar movement between finishing stands, shears, and cooling beds

- Hot Strip Mills & Wire Rod Mills – managing the transfer and deceleration of high-speed products

- Twin Channel Systems – precisely reducing bar speed to ensure smooth channel entry

- Shearing Sections – stabilizing the bar before it reaches dividing or crop shears

Looking for the most reliable reliable Pinch Roll and Tail Breaker solutions for your steel plant?

Trust A.G. Engineers – India’s most reliable manufacturer and exporter of Pinch Roll/Tail Breaker and allied rolling mill machinery.

Call +91-98550-30499 today for pricing, technical support or export inquiries.